Numerical Control with bSolid Software. The multi-document software application in a Windows environment allows you to design the finished product, define its machining operations, define the work plane, simulate the part machining operations on the 3D model of the machine, and generate the necessary machine programs.

bSolid - 3-Axis Machining

bSolid - 5-Axis Machining Module for surface machining with 5-axis units and interpolation movements on all 5 available axes (X, Y, Z, C, B). The module includes the following commands: · Assign roughing and finishing operations to three-dimensional surfaces · Spread or project a machining path lying on a plane onto a curved surface · Follow 2D or 3D curves with any type of tool

bSolid - 3D Engraving

bSolid - Import External Formats

Working Areas:

X = 5055 mm; Y = 1650 mm (may vary depending on configuration)

Z = 200 mm with H=74 mm modules

Z = 245 mm with H=29 mm modules

Workpiece loadable in Y:

1650 mm, with thickness up to 60 mm on H=74 mm modules

1600 mm, with thickness over 60 mm on H=74 mm modules.

10 ATS tables – 40 carriages. The code includes:

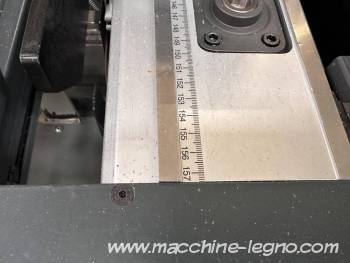

• 2 aluminum bars (1 left and 1 right) on which the lateral stops slide.

• 10 aluminum work tables. The tables slide on hardened and ground linear guides with recirculating ball bearings. Both the front and rear linear guides are locked by four pneumatic cylinders. The control is activated by a button located on the front of the work table. The carriages slide on steel guides positioned above the extrusion.

Pneumatic locking system divided into 2 locking zones in X

Automatic positioning (EPS) for worktables. "EPS" (Electronic Positioning System) device for automatic NC positioning of worktables and carriages, complete with locking devices to eliminate possible operator errors.

Rear row stop, with 140 mm stroke

Middle row stop, positioned at 405 mm, with 140 mm stroke.

Front row stop, positioned at 1460 mm, with 140 mm stroke

4 lateral stops, with 140 mm stroke (2 right + 2 left) with system

2 additional lateral stops, with 140 mm stroke (1 right + 1 left).

Sensor to verify the stop descent

12 clamping devices for clamping narrow workpieces

6 bar-type lifting devices for loading aids, for modules H=74 mm

Configuration 5A, for Rover B. Configuration for high productivity and flexibility, thanks to the two 4- and 5-axis machining heads and the ability to perform tool changes in parallel. Includes the axes and carriages for the movement of the main machining heads. Includes 2 inverters.

Second Y-axis. Introduces the separation of the front and rear Y-carriages, with independent motorization. The two Y-carriages have a maximum speed of 118 m/min.

13.2 kW (17.7 HP) electrospindle, HSK F63 connection, air-cooled. Main features: • 11 kW (14.7 HP) from 12,000 to 15,000 rpm in S1 service. • 13.2 kW (17.7 HP) from 12,000 to 15,000 rpm in S6 service. • Ceramic bearings. • Right and left rotation. • Rotation speed from 1,000 to 24,000 rpm programmable via NC. • Pneumatic release is via a prismatic linear guide and recirculating ball bearings. A chip extraction hood is included, with 6 different Z-positions managed by the NC, depending on the tool length, or by program. The extraction port is automatically closed when the electrospindle is not working. Provision for subsequent installation of the 360° machining unit (C-axis)

8-position turret tool magazine on the Y-axis carriage

13 kW (17.4 HP) 5-axis interpolating machining unit, HSK F63 connection, liquid-cooled. Allows the electrospindle to interpolate on 5 axes, managed by numerical control. To control the orientation of the machining unit, BIESSE uses a brushless motor driven by a digital drive and a "zero backlash" Harmonic Drive reducer. The 5-axis machining unit is anchored directly to the vertical carriage (Z-axis) without intervening pneumatic connections, thus eliminating additional tolerances that could negatively impact the unit's rigidity and machining precision. Thanks to the unit's compactness, it is possible to perform machining on areas of the workpiece that are inaccessible to other types of 5-axis machining units on the market. The electrospindle is equipped with ceramic bearings suitable for operating at high rotation speeds, has a pressurization system to protect against dust ingress, and an internal blower to clean the tool holder cone during tool change. For optimal heat dissipation from the electrospindle during machining, a liquid cooling unit is used. The 5-axis machining unit does not require periodic lubrication, as its components are lubricated for life. Main features: - 11.0 kW (15.0 HP) at 12,000 rpm in S1 duty. - 13 kW (17.4 HP) at 12,000 rpm in S6 duty. - Maximum rotation speed: 20,000 rpm. - C-axis travel: continuous 360° rotation. - C-axis rotation speed: 12.4 rpm. - B-axis travel in positioning: +/- 100°. - B-axis rotation speed: 12.4 rpm.

Flange for setting up a 5-Axis Interpolating Operating Unit for the installation of aggregates

Provision for deflectors with pneumatic sensors on 4- or 5-axis operating units

8-position turret tool magazine. Located on the X-slide, at the front of the beam, it can accommodate up to 8 tools, always available at any point on the machine.

Additional Z-slide.

BH 29 L drilling head with automatic lubrication. This work unit can accommodate up to 29 independent tools, for single and multiple drilling on 5 sides of the workpiece and channels with the blade in the X direction on the upper face. The spindles rotate alternately right and left via precision gears with ground helical teeth, ensuring maximum precision and quiet operation. The head is equipped with an automatic lubrication system whereby, at each time interval, predefined by the numerical control, a pump automatically sends the lubricant inside the head, without machine downtime and eliminating operator intervention. The head is composed of: -16 independent vertical spindles with 32mm spacing, of which 12 arranged in the X-axis direction and 4 arranged in the Y-axis direction -6 independent horizontal spindles with double output, arranged at 32mm spacing, of which 4 oriented in the X-axis direction and 2 in the Y-axis direction -1 circular blade dia. 120mm for channels in the X-axis direction (25mm useful cut) One motor powered by an inverter is used (power: 1.7 kW at 2800 rpm - 3 kW at 6000 rpm): the rotation speed of the spindles is variable up to 6000 rpm, to perform fast drilling cycles and therefore reduce processing times. Furthermore, the rotation speed can be selected based on the tool used and the material being drilled.

Coolant cooling unit

33-slot chain-type tool magazine - 120 mm center distance. Housed on the moving column in an "X" arrangement.

HSK F63 tool holder with integrated flange for blades that can be used on a 5-axis unit.

300 mm diameter blade for tool holder cone with integrated flange.

- Italy

- Second hand